The Story of Nickel – Part 2

The Story of Nickel – Part 2

As mentioned in Part 1 of the Story of Nickel, we will now turn our attention to the higher nickel alloys and their weldability.

However, prior to discussing that subject, let’s look at the history of nickel as is it jingles away in our pockets or wallets. What would appear to be Canada’s most iconic Loonie and Toonie were once made primarily from nickel.(Figure 1) Indeed, up to 2012 the Loonie was composed of nickel electroplated with aureate bronze (91.5% nickel, 8.5% bronze). However, the composition has now changed to multi-ply brass-plated steel.

In the same manner, the original Toonies outer ring was 99% nickel, and the inner core was a copper-aluminum-nickel alloy. Now the outer ring is multi-ply nickel-plated steel, and the inner core is multi-ply brass-plated aluminum bronze which can contain up to 7% nickel.

The 5-cent Nickel coin itself was 100% nickel up until 1982, then it changed to Copper Nickel and today its is made of nickel-plated steel (94.5% steel, 3.5% copper, and 2% nickel plating).

Turning back to the engineering use of high nickel alloys, these metal alloys, in the main, are selected because they provide the desired combination of mechanical properties, corrosion resistance, and both high and low temperature properties

They are defined by a system known as the Unified Numbering System or UNS system. Many of these alloys were originally developed by major producers and this is why some of them are known by registered trade names such as:

- Monel 400 (UNS N04400), based on the Nickel and Copper alloy system.

- Copper Nickel CuNi (C71500) also based on the Copper and Nickel alloy system

- Inconel 600 (N06600), based on the Nickel and Chromium alloy system with iron additions

- Hastelloy C276 (N10276), based on the Nickel-Molybdenum alloy system

Monel alloys see major usage in seawater environments due to their excellent resistance to corrosion, cavitation, erosion and applications involving their use in the presence of chlorinated solvents, sulphuric acid and alkali’s. Similarly, the copper nickel alloys are used extensively for marine corrosion systems.

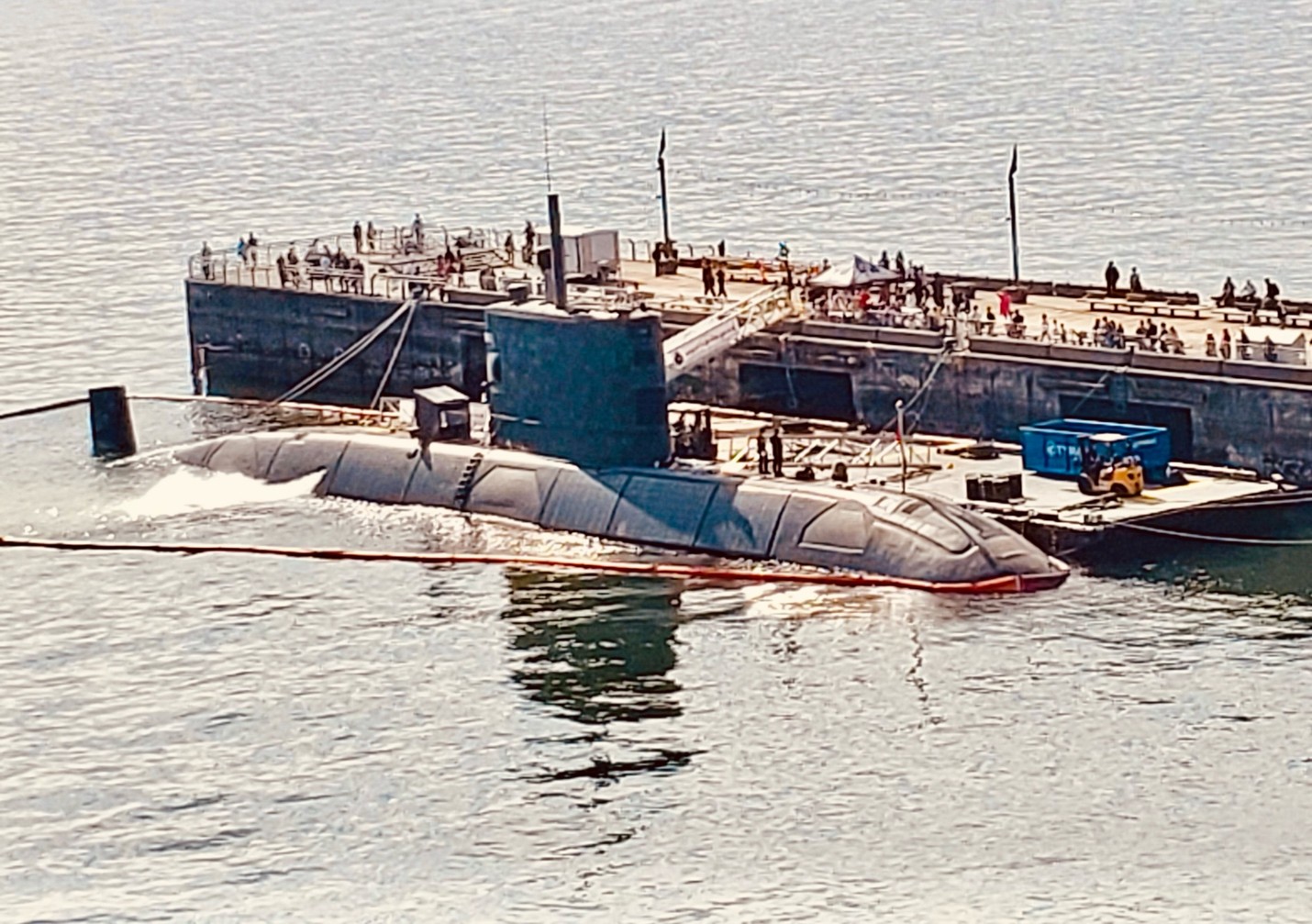

It is highly likely that Monel is used in seawater systems aboard Canada’s submarine fleet, as would be copper nickel. Figure 2 illustrates the submarine HMCS Cornerbrook, tied up at a pier in North Vancouver.

Inconel 600 would be used in severe corrosive environments at both elevated and low temperature while Hastelloy’s are amongst the most corrosion resistant metals available and are used over a wide range of both extreme reducing and oxidizing environments.

Table 1 illustrates three common wrought nickel alloys with their UNS numbers, trade names and their mechanical property data. The materials shown have a range in Nickel content from a high of 75% to a low of 52%.

There are several welding processes that can be utilized to join this wrought nickel and its alloys.

The most widely are those that are gas shielded, namely GTAW and GMAW and, of the fluxed processes, SMAW can also be used.

|

Alloy Name |

ID |

Ni |

Cr |

Mo |

Fe |

Nb |

Al |

Ti |

Others |

0.2%PS* |

UTS |

% El |

|

Monel |

N04400 |

68 |

|

|

1.75 |

|

|

|

Cu 33 |

235 |

562 |

38 |

|

Alloy |

N06600 |

75 |

15.5 |

|

8.5 |

|

|

|

|

305 |

670 |

40 |

|

Alloy |

N07718 |

52 |

19 |

3 |

REM |

5.2 |

0.5 |

0.95 |

|

1100 |

1420 |

18 |

Table 1.0: Some Common Wrought Nickel Alloys and Properties.(* Proof Stress)

In Canada there is no CSA Standard for filler materials to be applied to Nickel and its Alloys. We, therefore adopt the American Welding Society (AWS), system

There are two such specifications for high nickel consumables, these are:

AWS A 5.11 ‘Specification for Nickel Alloy Welding Electrodes for Shielded Metal Arc Welding”

AWS A 5.14 “Specification for Nickel and Nickel Alloy Bare Welding Electrodes and Rods

As an example, the classification system used by AWS A5.11 for covered electrodes follows a standard pattern. For example, the description below lays out an interpretation of the classification ERNiCu-7 which would be selected for the welding of the Monel alloys.

E Ni Cu-7

- E is Electrode,

- Ni Identifier for Nickel Based Alloy,

- Cu Principal Alloying Element,

- 7 a designator that separates compositions within the group.

In general, most filler materials normally match the parent metals. However, these filler materials can also contain small amounts of titanium, aluminum and/or niobium to reduce the risk of porosity and cracking.

Electrodes for gas metal arc and gas tungsten arc welding covered in AWS A5.14 use a similar classification system except that the designated E just becomes ER for electrode or rod.

As with the parent alloys, the filler materials can be trade named and those most used for the three alloys given in Table 1 are listed below the AWS Specification in Table 2.

|

Alloy |

UNS |

AWS A 5.14 |

AWS A 5.11 |

Trade Name |

|

Monel 400 |

N04400 |

ERNiCu-7 |

ENiCu-7 |

Monel 60 |

|

Alloy 600 |

N06600 |

ERNiCr-3 |

ENiCrFe-3 |

Inconel 82 |

|

Alloy 718 |

N07718 |

ERNiFeCr-2 |

|

Inconel 718 |

Table 2 Typical Nickel and Nickel Alloys and their Filler Materials

Of the above, the high strength Alloy 718 is designed as metallurgically hardenable and must be treated as such when welding, especially if matching strength is required. Additional important precautions are:

- The joint and wire cleanliness, which is a must

- The weld pool can be sluggish and does not flow freely as compared to carbon or stainless steels.

The chemistries of both the wire and covered electrodes are complex, some having as many as 20 elements. So, for further information the reader is directed to the AWS specifications referenced above.

In summary, Nickel and its alloys are used in a wide range of applications due to their unique properties, particularly their corrosion and heat resistance. They are essential in industries like aerospace, chemical processing, marine applications, energy, and consumer goods.

They are also readily weldable but precautions, such as cleanliness, must be observed.

Again, as noted in Part 1 of this story, Canada is richly endowed with nickel ores, indeed from coast to coast.

Mick J Pates IWE

PPC and Associates

Disclaimer

The information provided is intended for general interest, to educate and inform our audience. The CWB and those providing feedback to the questions do not take any responsibility for any omissions or misstatements that could lead to incorrect applications or possible solutions that industry may be facing.

How-It Works content is submitted by Industry experts to the CWB Association and does not necessarily reflect the views of the CWB Group. When testing for CWB Certification or CWB Education, please refer to CWB Education textbooks or CSA standards as the official source of information.