How is laser welding different from TIG (GTAW) or MIG (GMAW) welding?

How is laser welding different from TIG (GTAW) or MIG (GMAW) welding?

How is laser welding different from GTAW or GMAW welding? The major difference between laser welding and GTAW/GMAW is the fact that the laser process does not create an electric arc to join materials, like GTAW/GMAW, but creates a beam of high intensity radiation to join them.

We are aware that arc welding uses an electric arc to create the heat to melt and join metals. Basically, a power supply, using either direct (DC) or alternating (AC) current, creates an electric arc between a consumable or non-consumable electrode and the base material. The type of current selected depends on the welding activity i.e., for GTAW of aluminum alloys AC is preferred. Conversely, for steel fabrication, GMAW usually operates on DC current with the electrode being positive. Also, in the majority of cases, a filler material has to be supplied to the joint.

Laser beams are produced by a device that stimulates atoms or molecules to emit light at particular wavelengths and amplifies that light, typically producing a very narrow beam of radiation. The term “laser” is an acronym for “Light Amplification by Stimulated Emission of Radiation.

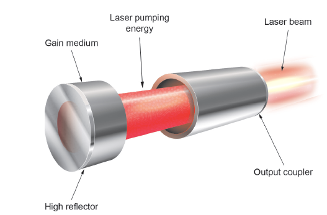

A laser producing device consists of a gain medium inside a highly reflective optical cavity, together with a means to supply energy to the gain medium. The gain medium is a material with properties that allow it to amplify light by stimulated emission. In its simplest form, a cavity consists of two mirrors arranged such that light bounces back and forth, each time passing through the gain medium. Typically, one of the two mirrors, the output coupler, is partially transparent and the output laser beam is emitted through this mirror.

The basic process is shown in Figure 1.

The principal components of a laser, as depicted in Figure 1 above are:

- The gain medium 2. The laser pumping energy 3. A high reflector 4. An output coupler 5. The laser Beam

The two main categories of lasers for welding are gas lasers and solid-state lasers. A common solid-state media is neodymium-doped YAG (yttrium-aluminum-garnet). Nd:YAG lasers which are used for welding steel and super alloys. Typically, for automotive applications where cutting and welding steel is required, the power levels are 1 to 5 kW. Gas lasers use high voltage, low current power sources to supply the energy needed to excite the gas mixture used as a lasing medium. Power outputs for gas lasers can be much higher than for solid state lasers. Carbon dioxide is a common gas laser for welding and cutting applications, using power levels up to 15 KW.

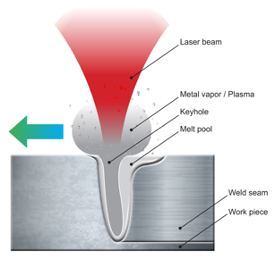

In laser welding, joining is by use of the so called “keyhole” technique and filler material is usually not required, the process is thus autogenous. The laser beam vaporizes a small column of metal at the joint and the area immediately adjacent to the beam melts. As the beam is moved along the joint, capillary action draws the liquified faces of the joint together, forming the fused area. Figure 2 shows illustrates the operation of the beam in the keyhole mode. The joint preparation is square and, the gap between pieces to be joined must be no more than 10% of the thickness of the thinnest component.

Some of the advantages of the LBW process over arc welding are:

- the process is easily automated with robotic machinery

- narrow welds are produced with a small, narrow heat-affected zone

- high processing speeds can be achieved, with rapid stopping and starting

- difficult to weld materials, such as titanium and quartz, can be welded

- filler metal is not required under normal circumstances

The major disadvantages over arc welding are the initial high and subsequent maintenance costs, together with a limitation on thickness. The thickness of steel to be welded by a laser operating alone is limited to 19 mm whereas, with arc welding, thicknesses to be joined can be significantly higher, the joining of 100 mm + steel is not unusual.

This thickness can be exceeded by using the so called “hybrid laser” welding technique.

Laser hybrid welding is a type of welding process that combines the principles of laser beam welding and arc welding, the principles of which may be covered in a future article.

Mick J Pates, President

PPC and Associates

Disclaimer

The information provided is intended for general interest, to educate and inform our audience. The CWB and those providing feedback to the questions do not take any responsibility for any omissions or misstatements that could lead to incorrect applications or possible solutions that industry may be facing.

How It Works content is submitted by Industry experts to the CWB Association and does not necessarily reflect the views of the CWB Group. When testing for CWB Certification or CWB Education, please refer to CWB Education textbooks or CSA standards as the official source of information.