The Story of Nickel – Part 1

The Story of Nickel – Part 1

Introduction

Nickel is an extremely important metal and is found on Earth in a combination with iron, a reflection of the origin of those elements as major end products of a supernova explosion of particular star types in outer space.

Although most of the nickel in the earth's crust exists as oxides, the economically more important nickel ores are those we find as sulfides. Major global production sites include the Sudbury region here in Canada, the New Caledonia region in the Pacific, in Western Australia, and Norilsk, Russia.

There are other deposits in Canada, notably in Quebec and Newfoundland and Labrador. However, perhaps the most significant finds are those in Ontario where there are deposits in the “Ring of Fire”, north of Thunder Bay and the Crawford mine, which is located near Timmins. The Crawford mine is currently undergoing assessment for future development and, its larger area, appears to be a possible base metals and critical minerals centre for North American battery manufacturing and for EV automotive companies.

Besides containing a nickel reserve in the order of 3.8 million tonnes, the proposed Crawford mine and mill project contains other very important minerals. The mine is planned to produce primarily nickel but also, cobalt, platinum, palladium, iron ore, and significant tonnage of chromium. The current planning will also bring more processing capacity to the northern Ontario area with the possibility of making stainless steel product for the North American market. Nickel is the critical component in making austenitic stainless steels austenitic.

In addition to these Ontario finds, there are now two new nickel mines proposed for B.C. The Baptiste project near Fort St. James and the Turnagain project in northwest B.C. The Turnagain Project is being heralded as among the largest undeveloped nickel sulphide deposits in the world.

It should also be noted that Nickel is one of four elements, the others are iron, cobalt, and gadolinium, that are ferromagnetic at about room temperature.

Some Additional Canadian notes:

- In 2022, Canada produced 143,000 tonnes of nickel and ranked sixth in the worlds nickel production.

- Canada's exports of nickel and nickel-based products in 2022 were valued at $7.5 billion.

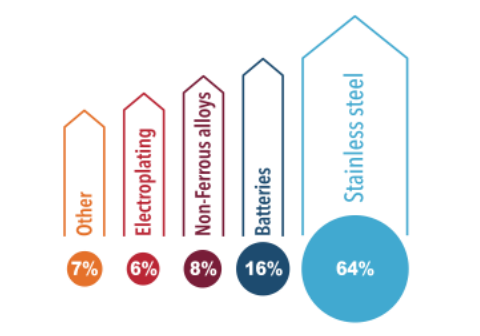

About 68% of world production is used in stainless steel with about 16% of current global production going toward electric batteries. The balance is used for nickel-based and copper-based alloys, for nickel plating and for alloy steels. Nickel is a crucial component in many electric vehicle (EV) batteries, with the two most common types, Nickel Cobalt Aluminum (NCA) and Nickel Manganese Cobalt (NMC), containing up to 80% nickel. So, nickel is a cornerstone toward electrifying the world’s transportation and providing clean energy storage options. The global use of Nickel, in 2023, is illustrated in Figure 1 below.

Nickel in Canada is refined using a variety of methods in refinery’s currently located in:

- Fort Saskatchewan, Alberta

- Sudbury, Ontario

- Long Harbour, Newfoundland and Labrador

The metal and its Alloys

Pure nickel is resistant to corrosion in water or air, and therefore is used as a protective coating. It is malleable and ductile and readily soluble in dilute acids, but is not affected by alkalis

Pure nickel, designated UNS N02200, is used in the chemical industry for its corrosion resistance - particularly to alkalis. It is also used for its properties in shielding against electromagnetic interference and in transducers.

Stainless steels

A large group of alloy steels ranging from 18% chromium, 8% nickel, and to even higher chromium, and nickel contents are employed where corrosion resistance is a major requirement.

In addition to their inherent corrosion resistance, nickel-containing austenitic stainless steels are easy to form and weld; they remain ductile at very low temperatures and yet can be used for high-temperature applications. In addition, unlike conventional steel and low-nickel, ferritic stainless steel, they are non-magnetic. This means they can be made into an exceptionally wide range of products, spanning applications in the chemical industry, the health sector and domestic uses. As a point of fact, nickel is so important that the higher nickel-containing grades make up around 80% of stainless-steel production. The best-known of these are Type 304, which has 8% nickel and Type 316, which has up to 11%.

A spool piece made of austenitic stainless steel, 304L grade, is shown in Figure 2 below, this spool is to be used in a lithium separation plant in Quebec. Lithium of course is used in batteries that also contain nickel, hence this spool, containing about 8% nickel material, is part of a virtuous circle.

High Nickel Alloys

Nickel will alloy readily with many other metals, including chromium, iron, molybdenum and copper. This allows for a wide variety of alloys that demonstrate outstanding resistance to corrosion and high-temperature scaling, exceptional high-temperature strength and other unique properties, such as shape memory and low coefficient of expansion.

Some examples of these alloys are:

Monel: Primarily a mixture of Nickel and Copper

Alloy 600: An alloy containing high levels of Nickel with Chromium and Iron as a balance.

Alloy 718: An alloy containing high levels of Nickel with Chromium Molybdenum and Niobium.

In the next edition of the Story of Nickel we will peel back more information on these higher Nickel Alloys and describe how these very important materials are welded.

Mick J Pates IWE

President PPC and Associates