Differing Joining Approaches – Part 1

Differing Joining Approaches – Part 1

A lot of welding takes place with relatively simple joints in relatively simple positions. For example, in the structural world, many metres of fillet welds are deposited in a single pass in the 2G horizontal position. Also, there are many relatively thin butt welds which can be completed by a two-pass sequence, welding from both sides, with or without the need to back gouge. Such butt joints can also be welded from one side onto a backing bar and our structural welding code for steel, CSA W59, dictates that many of these joints are pre-qualified. The AWS D1.1 fabrication code for steel applies similar rules.

Now and then, we are faced with much thicker materials to join with much different end product requirements. In this short article we will look at the joining of two very thick carbon steels with different approaches and why these approaches were taken.

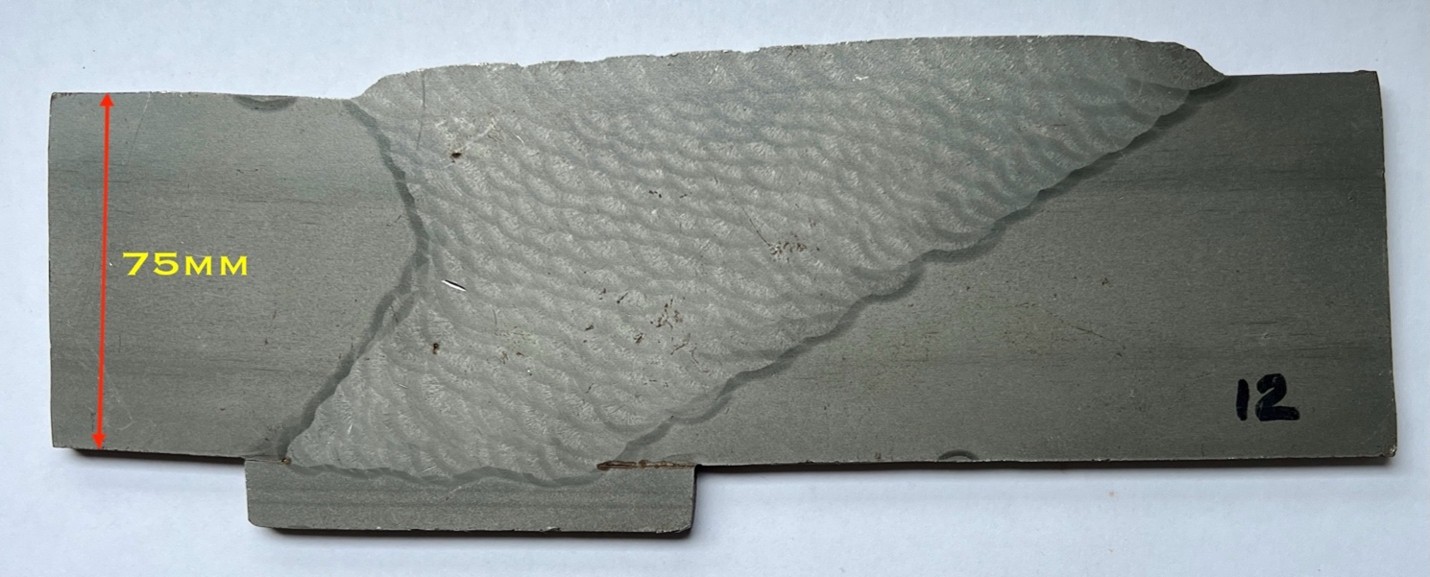

The two joints we will address are in thicknesses of 75 and 140 mm (3.0 and 5.5 inches). Figure 1 below illustrates a macrosection of a multipass Shielded Metal Arc Weld (SMAW) in a 75 mm thick carbon manganese ASTM A 516 Grade 70 steel. The joint was deposited in the horizontal (2G) position. The question we must ask ourselves when observing this macro section is why so many passes, approximately 200, and why was the SMAW process selected.

The macro shown is actually a mock up, welded as part of welding procedural development project. The finished weld required a toughness, as dictated by the design, and this toughness was required at a low temperature of operation. The toughness, as measured by the CVN test, was required in both the weld metal and the HAZ. From a joining perspective we can again ask.

- Why was the SMAW process selected and

- Why are there so many small passes

The answer to the first question is that the production joint itself was “in the field” and it presented a number of access problems. These access problems were such as to limit the amount of equipment that could be positioned in close proximity to the joint. Accordingly, the SMAW power source, without need of ancillary wire feeders, gas shielding bottles and associated cables and gas feeding lines was the eventual and the simplest solution.

Secondly, in order to achieve the CVN toughness required it was necessary to control the heat input which, in turn, would control the speed of joint cooling, commonly expressed as the joint cooling rate. For any given set of circumstances, in carbon manganese steels, high heat input/slow cooling reduces toughness and the aim here was a low heat input/fast cooling rate which leads to higher toughness.

This meant that the size of each deposited pass was quite small. With this approach the procedure was successfully qualified to meet design requirements and was released for production.

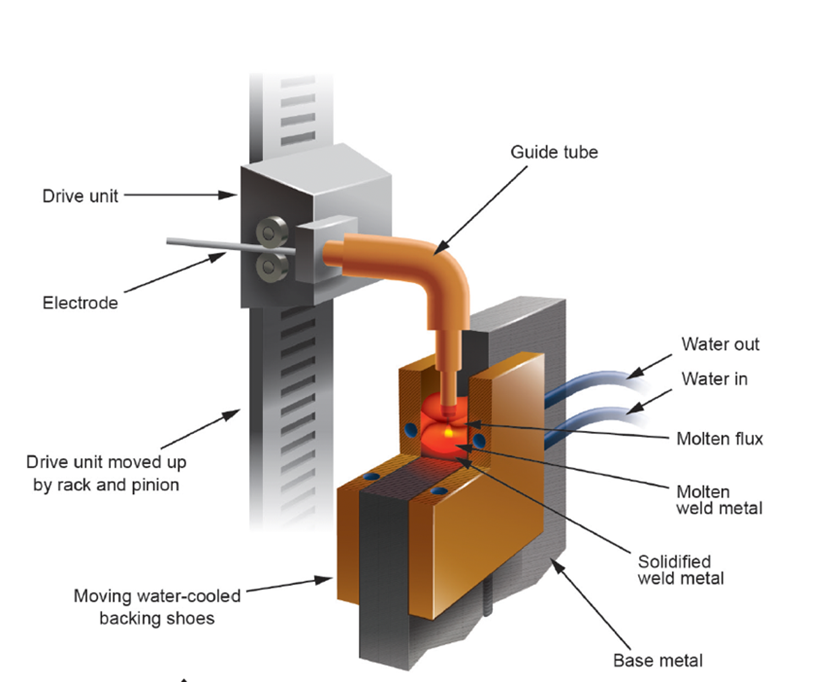

In the second case, the welding of a 140 mm thick joint, we will turn our attention to a welding process capable of joining very thick sections in just one pass. The process is the Electroslag Welding process (ESW) and it is designed to join plates set up in the vertical position and, to literally pour weld metal into the joint gap.

The equipment used for ESW consists of a direct current type constant voltage power source, a constant speed wire feeder, a guide tube (non-consumable or consumable), and copper shoes. The method utilizes a welding head that moves up the joint as the weld is made with the plates to be joined set in the vertical position. Water cooled backing shoes move along the joint and rise with the welding head. The arrangement is depicted in Figure 2.

The method is the very opposite of the earlier low heat input SMAW process. The earlier SMAW weld had heat inputs in the order of 1Kj/mm whereas the ESW process has a heat input many, many times greater than that. As a result, the final weld joint can have relatively low toughness due to the coarse grain size exhibited from high heat input/ slow cooling rate.

This process is recognised in both CSA W59 and AWS D1.1 but, for establishment of property data and other reasons, the process does not carry pre-qualified status. Therefore, each joint must be qualified by procedure.

This 140 mm thick shop weld, which was also in A 516 Grade 70, is shown in Figure 3. The joint was achieved in one pass using triple wires oscillating in the joint gap as the welding progressed upwards.

Once more, the completed joint required toughness at a given design temperature and, because of the extremely large grain size exhibited, these toughness’s were not obtainable in the “as welded” condition.

The solution to this was to give the completed “as welded” joint a heat treatment. In this case a normalizing treatment was performed on the finished weld. Normalizing completely breaks down the large grains size and allows for the reclamation of toughness due, in part, to the new smaller grain size that results from the treatment.

So, in conclusion, these two very thick joints, in the same kind of steel, were joined in completely different ways to achieve the design requirement for each joint.

The approaches taken illustrate the “art”, “science” and “breadth” of welding engineering focusing, in these cases, on the implementation of welding processes, systems and metallurgy that resulted in welds that met both the performance requirements and those of the applicable codes.

Mick J Pates IWE

President PPC and Associates

Disclaimer

The information provided is intended for general interest, to educate and inform our audience. The CWB and those providing feedback to the questions do not take any responsibility for any omissions or misstatements that could lead to incorrect applications or possible solutions that industry may be facing.

How-It Works content is submitted by Industry experts to the CWB Association and does not necessarily reflect the views of the CWB Group. When testing for CWB Certification or CWB Education, please refer to CWB Education textbooks or CSA standards as the official source of information.